Sword of Emperor lelouch

September 2009

Code Geass is a Japanese anime series set in an alternate timeline, which focuses on how the former prince Lelouch VI Britannia obtains a power known as Geass and decides to use it to obliterate the Holy Britannian Empire, a superpower that has been conquering various countries.

I was commissioned to build the sword of Emperor LeLouch. A scabbard to fit it was also requested.

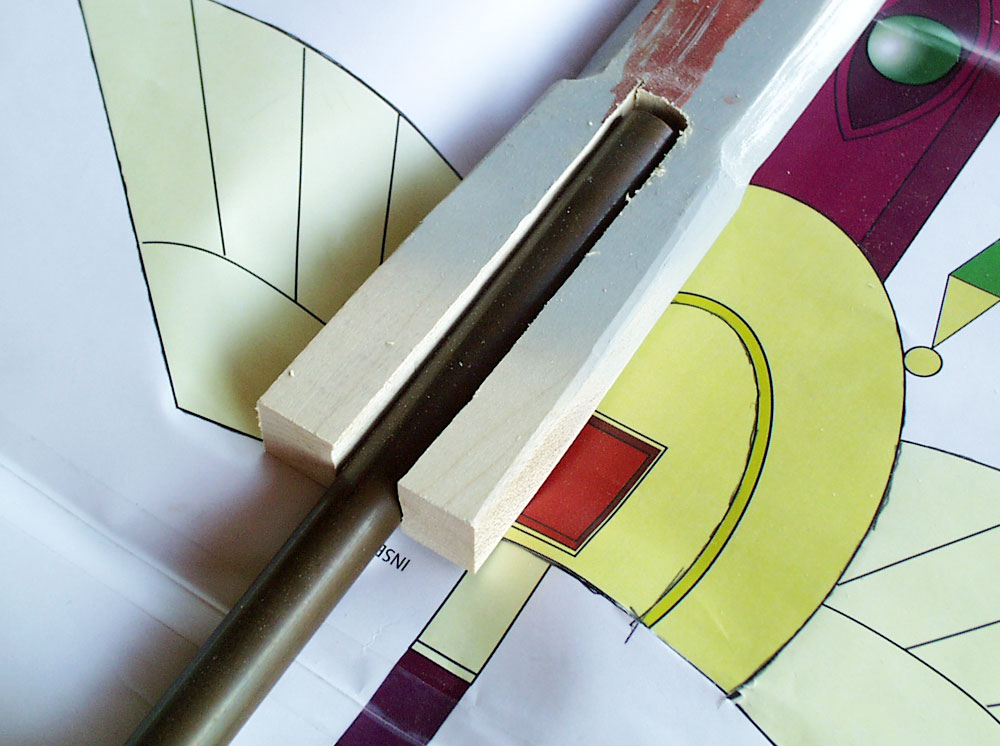

Since the blade is so thin, it would be difficult to insert a steel rod like my other wooden swords. I decided to make it from a solid piece of 3/4″ maple, cutting the side profile on the table saw.

I then tapered the thickness of the blade using the belt sander.

I used a hand plane to bevel the edges of the blade.

I cut a slot in the top of the blade big enough to insert a 1/2″ copper pipe which will serve as the handle.

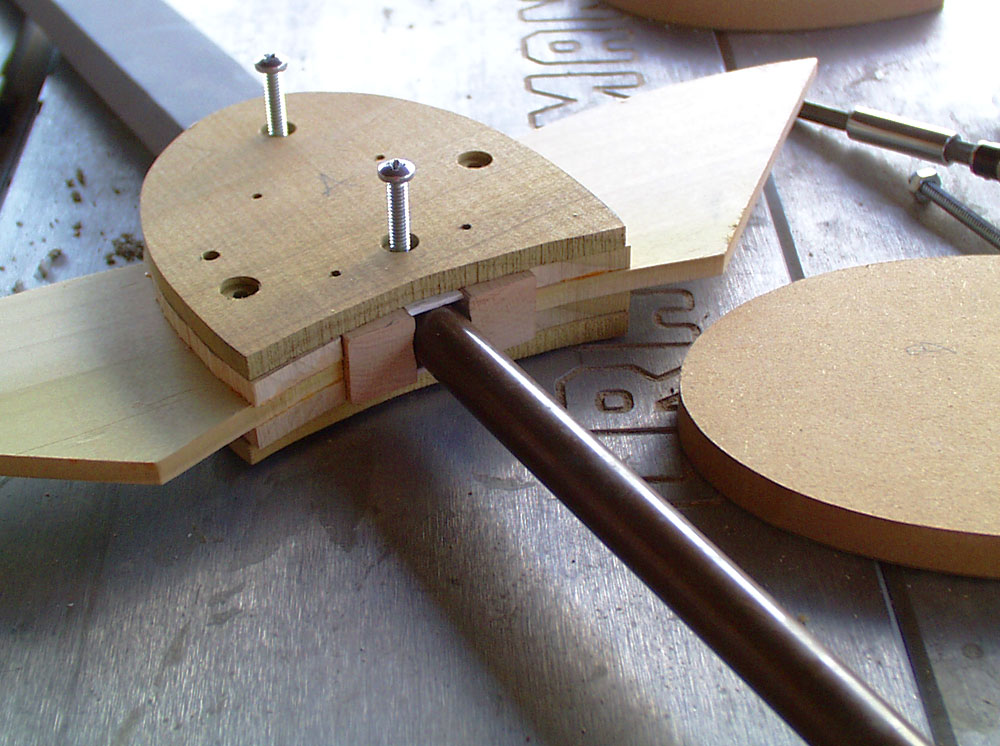

I cut 1/2″ MDF for the guard, running bolts through all the pieces to hold them together.

The guard was getting too thick, so I re-cut it in 1/4″ thick MDF.

I then cut the wings from 1/4″ poplar and filled the gap between the MDF with more poplar.

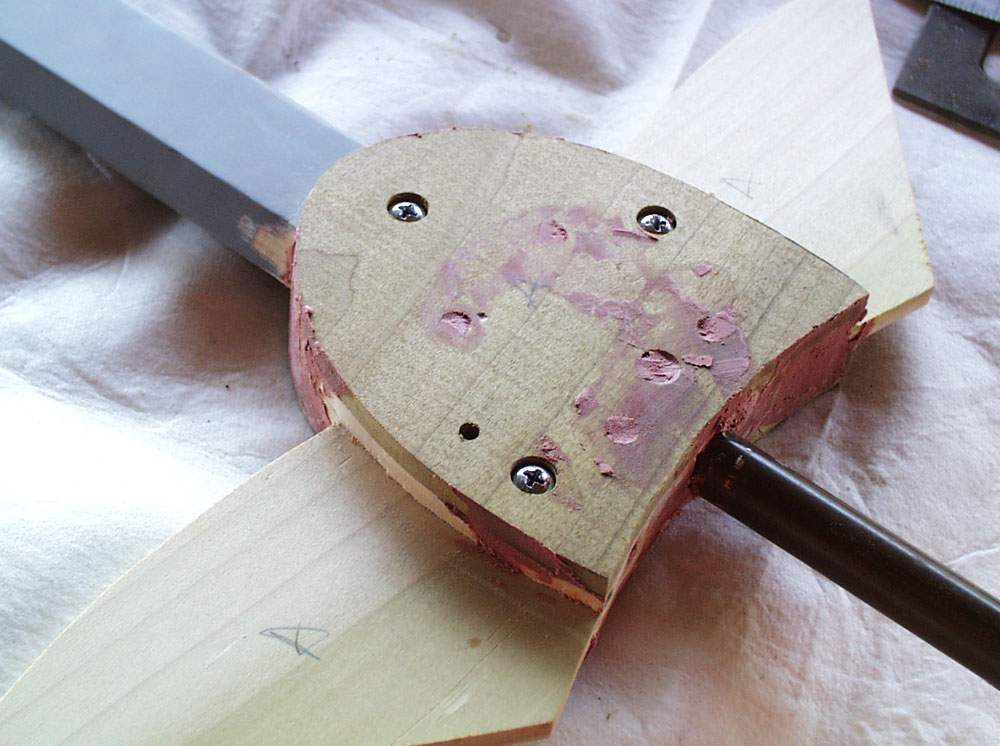

Once everything was bolted and glued together, I puttied up the seams.

To further reduce thickness, I also re-cut the outer trim from 1/4″ poplar. These also cover the bolts.

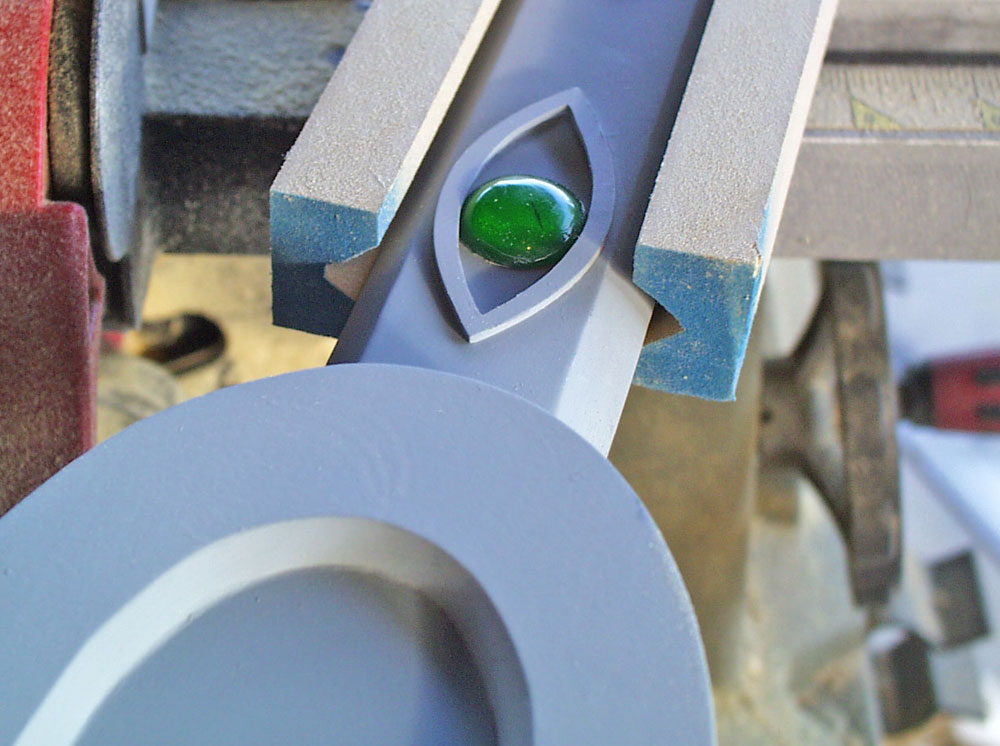

I routered out some shallow holes in the sides of the blade to hold the gems. I also cut some thin plastic to smooth out the bottom of the hole.

I made the blade gems using 1/4″ acrylic, shaping it with a Dremel sanding drum.

After sanding, the gem was smoothed with a buffing wheel.

I cut trim from styrene and glued them to the holes.

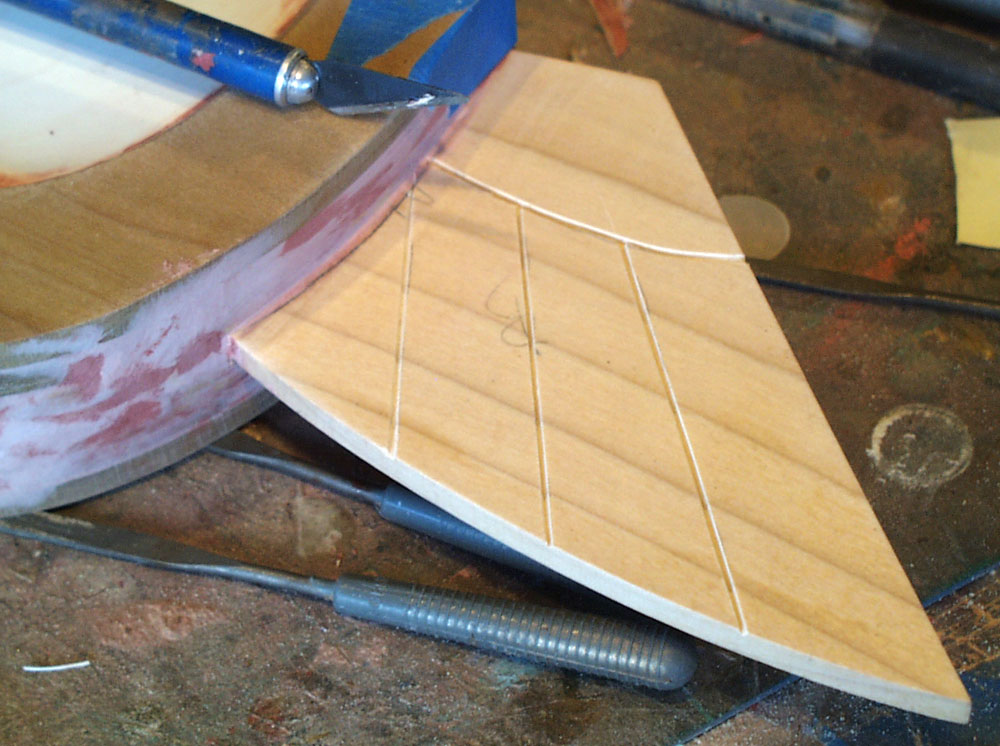

The feathers on the wings were scribed using an Xacto knife.

The handle trim was made by heating and wrapping thin styrene strips.

Once it was wrapped around, it was trimmed flush. The ends were heated again and the softened plastic was mashed together, welding the seam shut..

The plastic trim glued to both ends of the grip.

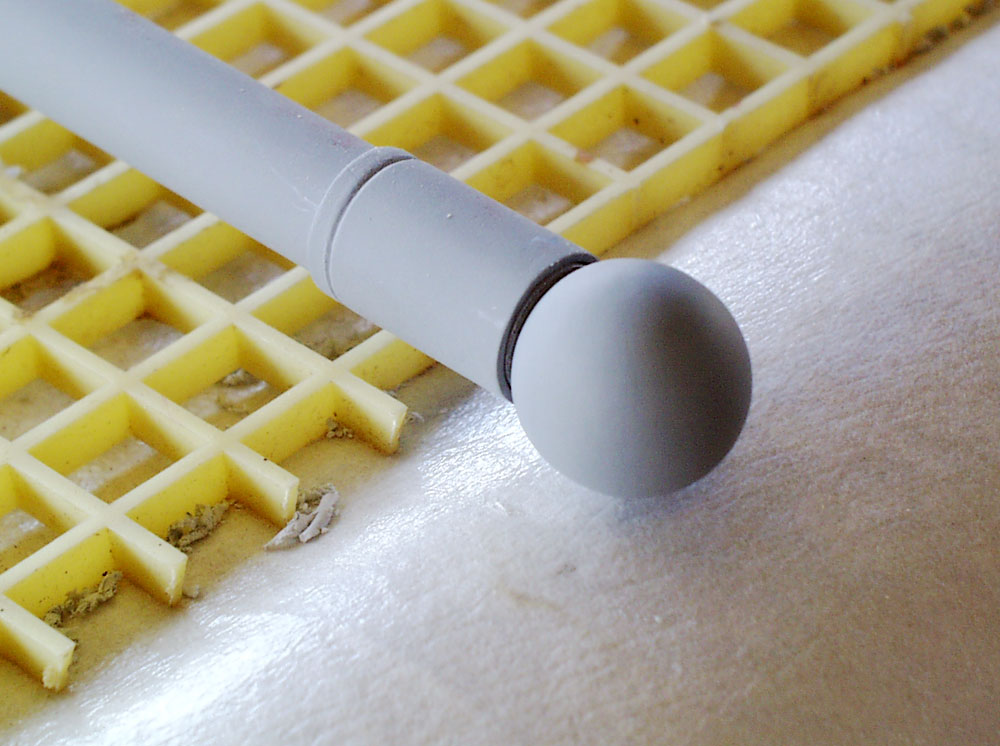

The pommel was a wooden drawer knob, secured with a threaded rod.

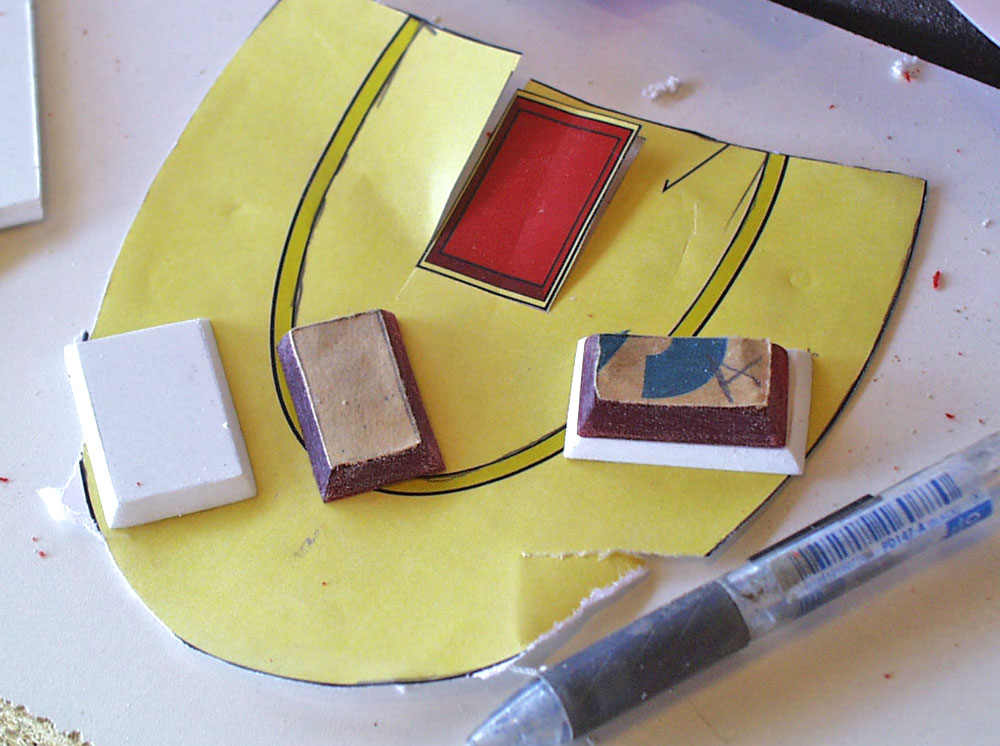

The hilt gems were cut from 1/4″ red acrylic. The base was cut from thick styrene.

I glued mylar wrapping paper to the back of all the gems which reflects light through the plastic, really making them shine.

I painted the hilt in two gold tones.

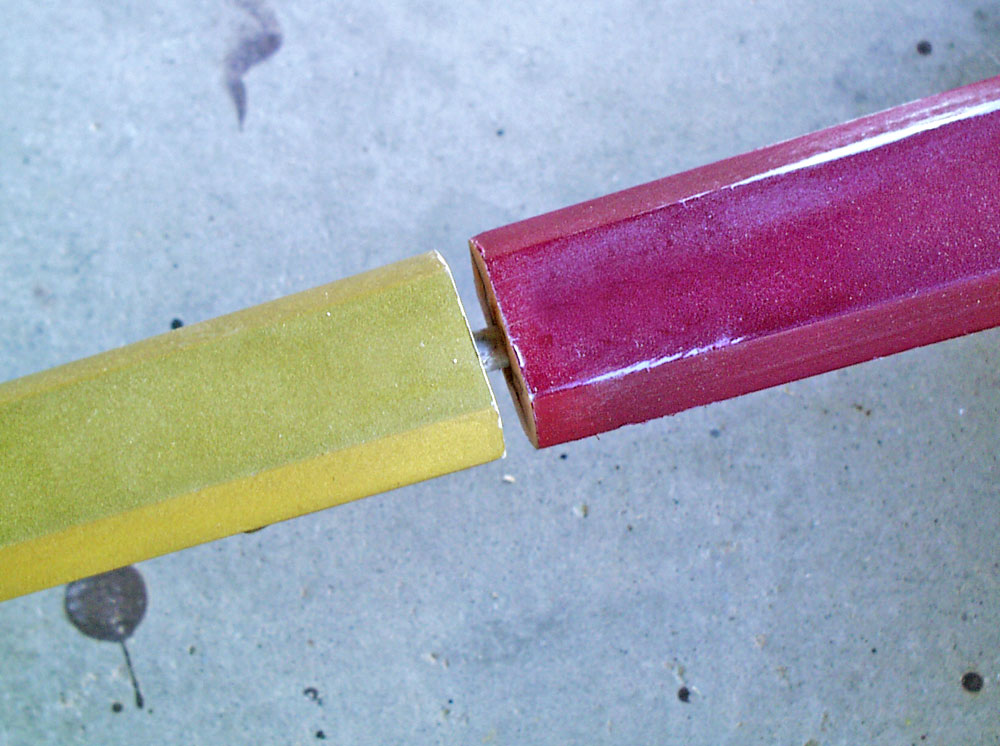

When I got a shipping estimate, I found that the sword was too long to ship cross country for a reasonable price. The only solution was to cut the blade in half so it fit in a smaller package.

Fortunately there is a natural color split at the halfway point so the split wouldn’t be too noticeable.

I drilled each end and glued an aluminum dowel into one side. The dowel in combination with epoxy will make the blade as strong as the original wood.

Back together! The client will epoxy it when he gets it.

The round beads were purchased and painted but I made the long beads from maple.

I glued some string into the end of the long bead and strung the round beads and grommet onto it.

The final sword.

I also built a scabbard for the sword.

I added two rings to the scabbard so that it could be worn from a belt.

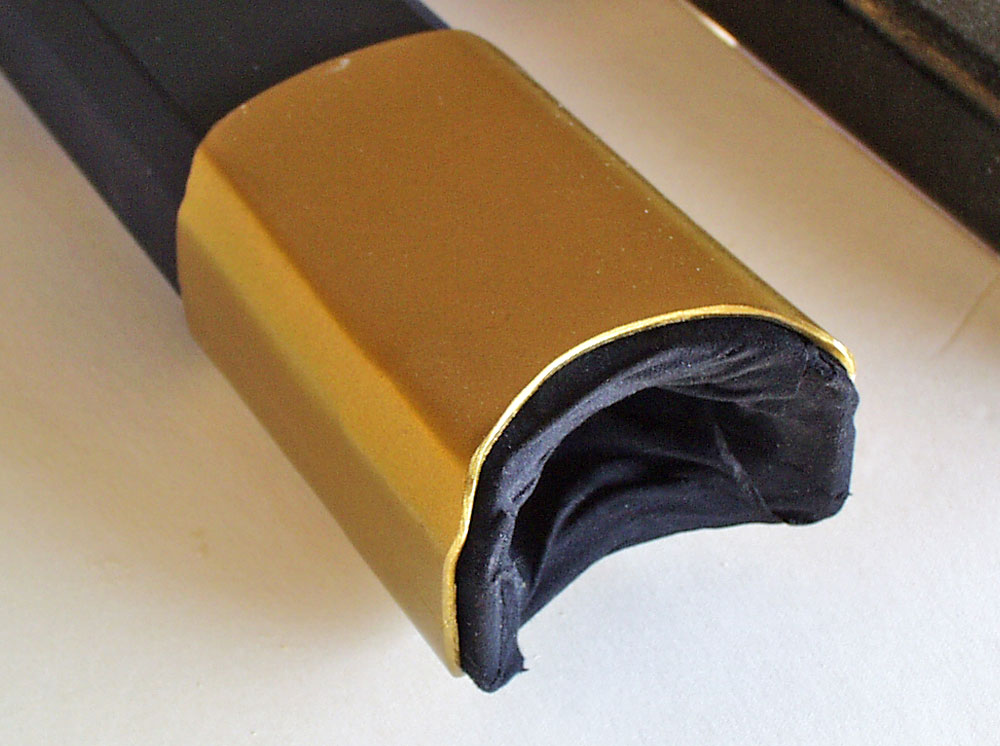

I heat formed styrene trim to the opening, keeping the trim away from the end to protect the sword from getting scratched.

The tip was also formed for heated styrene.

The sword outside the scabbard. The sword itself is over 5 feet long.