blaster contest

june 2006

A blaster is a fictional ranged weapon that fires bursts of intense energy that can kill or paralyze their target, depending on the setting. The term blaster is often used interchangeably with the term laser in everyday conversation, both denoting the same type of particle beam weapon.

This gun was built for a contest run every year by the Blaster Builder’s Club. The rules state that you must create a blaster of your own design using a toy gun as a base. I started with a partial M-16 that I had sitting in my scrap plastic box for 20 years.

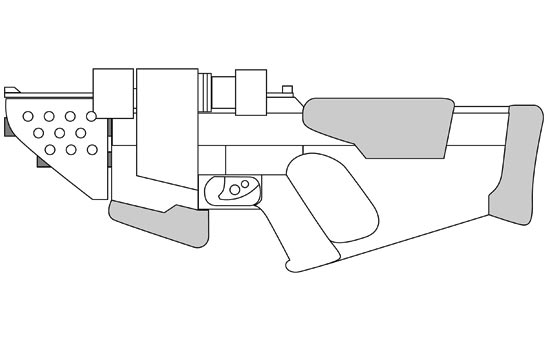

Measuring this, I started designing my blaster, first in Illustrator to work out the basic look…

…and then in Strata3D to fine tune the design and work out all the dimensions.

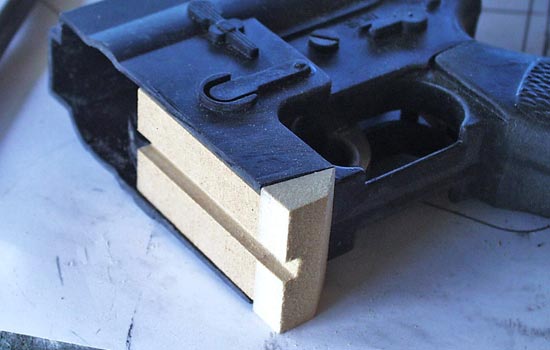

The stock, handle/sight and half of the magazine were hack sawed off the toy to make room for the new parts. A plug of MDF was glued into the magazine well for rigidity and to guide the new magazine.

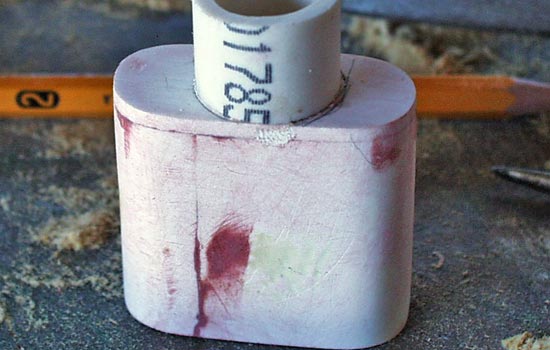

For the new stock I glued two pieces of scrap 3/47″ MDF together and shaped it with a jigsaw and Dremel. The barrel is a length of PVC pipe.

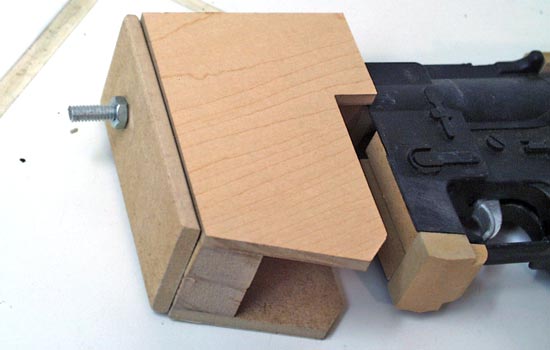

The new magazine well was made from MDF as well as the “plate” that will eventually hold the muzzle shroud. All were attached using the threaded rod (test fitted here).

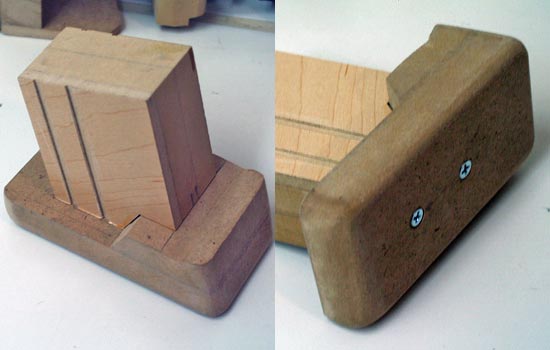

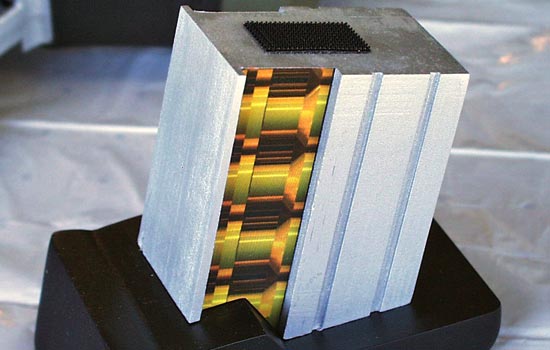

The magazine was also built out of MDF. The channels were cut using the table saw. The screws secured the base to the magazine but were left exposed (for looks).

The magazine fit like a glove, needing no mechanism to hold it in place.

A test fitting of the progress.

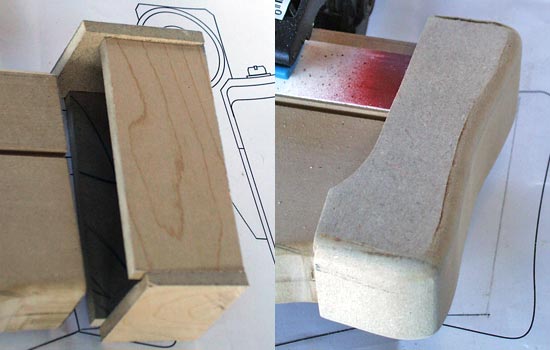

The butt plate started as a simple MDF box and was shaped on the belt sander to smooth all the edges.

The faux barrel was made by shaving a sliver off a 1-1/2″ PVC pipe.

The receiver cover started as a simple MDF box, with notches and supports allowing it to fit over the toy gun.

I wanted to preserve some of the nice detail on the side of the receiver. The M-16 has some cool looking switches.

I used scrap styrene to build new geometry on the sides while still taking advantage of the details I like.

Looking through my greeblie box I ran across an I.V. valve from when my cat was sick.

I split it in half and applied them to both sides.

IV lock on the left side.

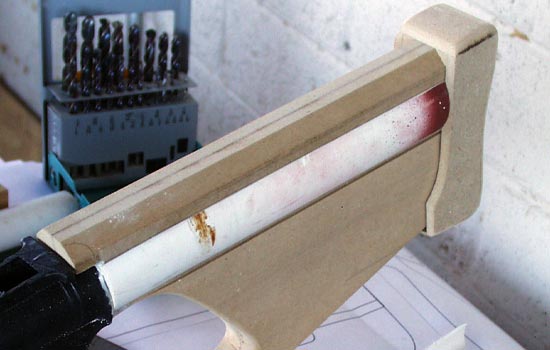

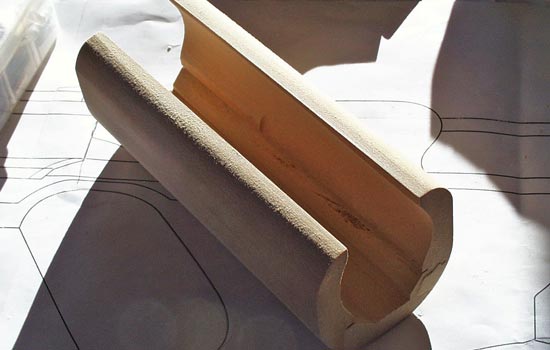

The cheek guard was a bit tricky as it had to wrap over the flat top of the stock as well as the round tubing of the barrel extensions. I glued together 3 pieces of MDF with appropriate notches.

Rounding the edges with the belt sander…

…cut away excess….

…and it slides on from the end.

The front of the scope was formed by melting a scrap of styrene around an oval piece of MDF.

The pieces for the scope: 1″ PVC to attach the front lens, Lathed wood for the body of the scope and a piece of 2″ PVC for a last minute addition to the eyepiece.

To fake a lens, I grabbed some sunglasses from an eye exam and trimmed out the rear lens.

I painted the rear scope body and added a screw knob I found in the “screw can”. The assembled rear scope. The “lens” is held in place by the PVC eyepiece.

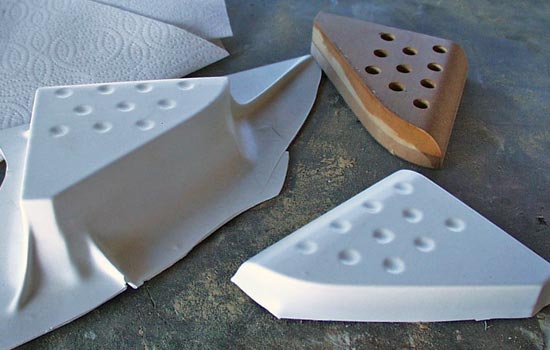

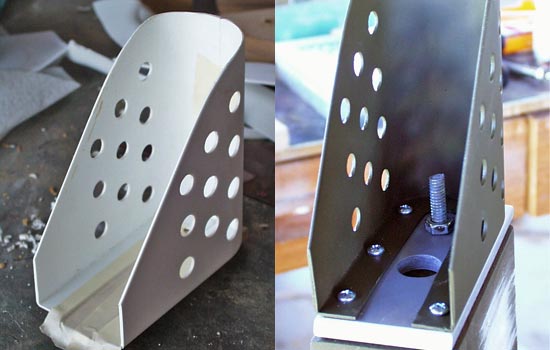

The barrel shroud was vacuformed over MDF masters.

They were trimmed and glued together with a thin strip of styrene along the seam for strength. The shroud was then screwed to the plate.

After I painted the magazine, I decided to re-address the issue of a transparent window. But as I was in the final weekend before the deadline, I “cheated” and just printed them on a sticker! I needed a way to keep it in so a spot of Velcro did the job.

The final scope attached to the rifle with exposed hex screws.

The final submitted photo

This year’s competition was extremely tough but I managed to tie for first place. In a tie breaker vote, I won the top spot! This was a fun and educational project to work on. I spent about 24-30 hours constructing it and only had to spend $16 on paint.